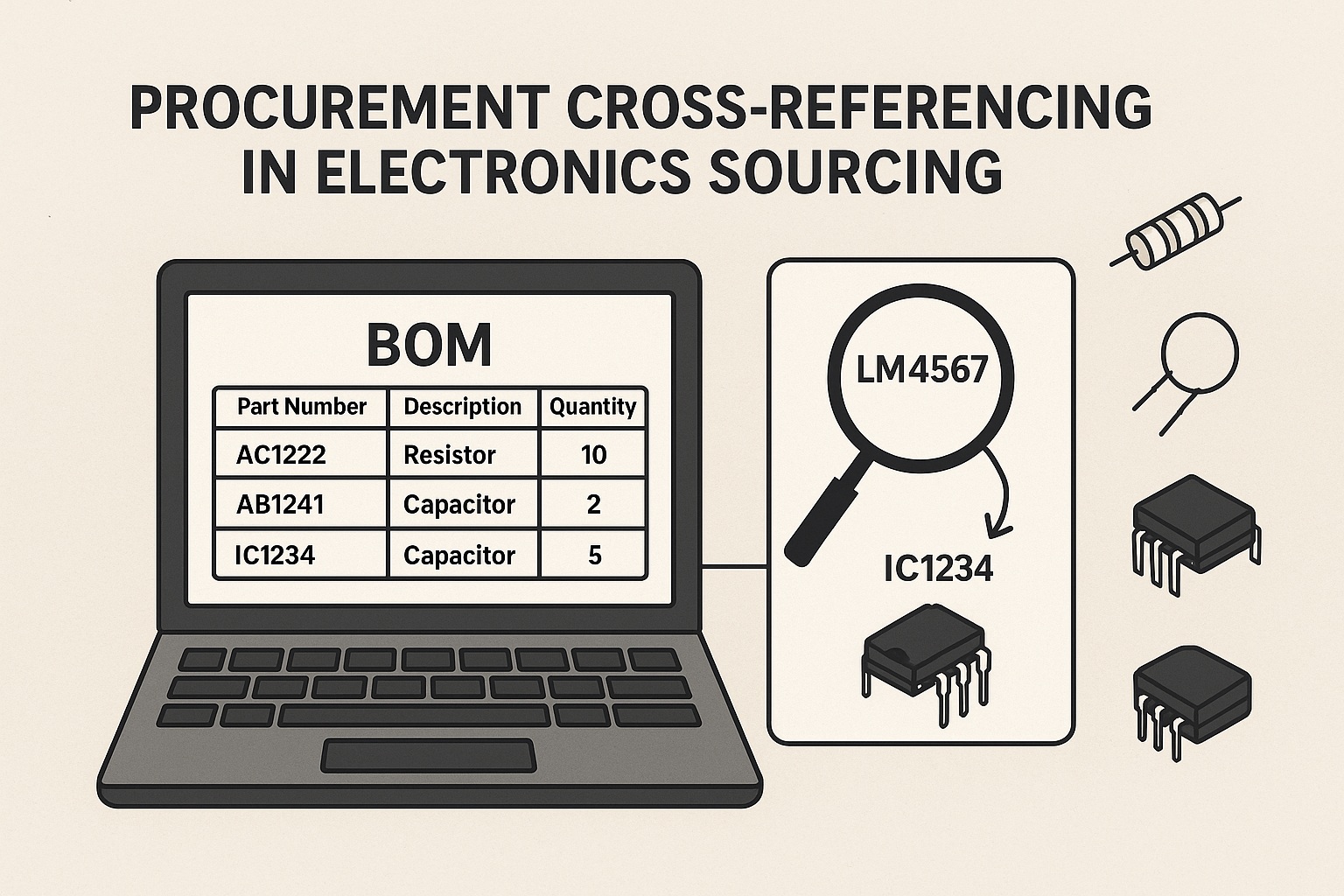

Ever find yourself drowning in conflicting part numbers, mystery substitutes, or that soul-crushing moment when a BOM lands on your desk with components no one’s ever heard of? You’re not alone.

Cross-referencing isn’t just helpful, it’s a lifeline. When done right, it can rescue your sourcing process from errors, delays, and panic purchases. Here’s how to take control.

Why Cross-Referencing Matters

Cross-referencing helps you match parts across different manufacturers, systems, or data formats. It’s how you:

-

Identify equivalent or alternate components.

-

Validate questionable part numbers.

-

Break down silos between your ERP, BOMs, and supplier catalogs.

As the gateway to multi-sourcing, cross-reference is foundational to supply chain resilience.

Real-world pain point: One part number might show up under five different aliases depending on whether you’re looking at the manufacturer, distributor, internal system, or a 10-year-old BOM. That’s a sourcing headache waiting to happen.

How to Do It Right

Here’s what best-in-class cross-referencing looks like:

Standardize Part Number Formats

Start by cleaning house. Align internal naming conventions so you can actually compare apples to apples.

-

Strip non-essential characters.

-

Use consistent suffix handling (e.g., -TR for tape & reel).

-

Normalize packaging and tolerance codes.

-

Confirm your MPNs with an aggregator like Octopart.

Why this matters: You can’t automate or scale anything until your internal data speaks the same language.

Consolidate Data Sources

Cross-referencing works best when you’re pulling from a single source of truth. That means:

-

Integrating supplier catalogs, BOMs, and your ERP.

-

Centralizing spreadsheets and scattered records into one structured database.

Tip: Start with your top 20% most used parts. Get those clean and cross-referenced first - then expand.

Leverage External Databases

Don’t go it alone. Use trusted sources like:

-

Octopart - Great for quick lookups and spec matching.

-

SiliconExpert, Accuris - For enterprise-class alternates.

These tools fill in the gaps when internal data falls short. Many can even integrate directly with your systems via API.

Automate Matching Rules

Manual matching doesn’t scale. Use logic and algorithms that can:

-

Match parts based on electrical characteristics.

-

Filter by RoHS or conflict minerals compliance.

-

Flag packaging or temperature range mismatches.

Bonus tip: Set up business rules so the system can suggest alternates automatically when a primary part goes obsolete.

Maintain Audit Trails

Every cross-reference decision should come with a paper trail:

-

Who created it?

-

When was it last reviewed?

-

What was the source?

This is especially crucial for regulated industries or anyone tired of re-validating the same decisions every six months.

Tools That Can Save Your Sanity

Don’t rely on spreadsheets. Seriously. Here’s what to look for in cross-referencing tools:

PLM Software

Product Lifecycle Management platforms like Arena or Agile PLM often include built-in cross-referencing tied to lifecycle stages.

-

Great for keeping track of alternates.

-

Helps align engineering, procurement, and compliance teams.

ERP Systems

Your ERP is the mothership, and it should support alternate parts directly in the item master or sourcing rules.

-

Look for multi-vendor part linking features.

-

Make sure engineering changes propagate through sourcing logic.

AI-Powered Platforms

AI tools can chew through thousands of lines of component data and surface non-obvious equivalencies, even flagging parts that might fail compliance checks.

-

These tools are pricey but powerful.

-

Worth it if you’re handling large, fast-turn BOMs across multiple product lines.

API Integrations

Your tools should talk to each other. APIs let your ERP sync with external databases in real-time, so you’re not relying on stale part data from six months ago.

Example: Pulling part status from SiliconExpert nightly keeps your procurement team ahead of obsolescence surprises.

Keep Your Data Sharp

Cross-referencing is only as good as the data behind it. Garbage in, garbage out. And in procurement, that garbage can cost you millions.

Validate Source Data

Always check part numbers against manufacturer datasheets before locking in a substitution. Don’t trust vendor descriptions blindly.

Implement Data Governance

Assign ownership. Someone (or some team) should be responsible for maintaining cross-reference accuracy.

-

Set review cycles.

-

Document changes.

-

Lock down edit permissions.

Conduct Regular Audits

At least quarterly, audit your database for:

-

Obsolete parts

-

Duplicate entries

-

Conflicting cross-references

This keeps your system lean, current, and trustworthy.

Wrap-Up: Turn Cross-Referencing into a Superpower

Here’s the truth: cross-referencing isn’t glamorous, but it pays off big.

When you do it right:

-

Your sourcing team reacts faster to shortages.

-

You unlock cost savings through alternate vendors.

-

You build a system that scales with product complexity.

And most importantly, you stop running in circles every time a part number changes.

So go ahead. Clean your data. Build those reference links. Set up the automations. Because in the chaos of electronics supply chains, solid cross-referencing is how you stay one step ahead.

Want cross-references at no cost? Visit X-Refs.com