Suggesting the wrong capacitor to an engineer is a quick way to get your email ignored. But when a part goes obsolete, is backordered for months, or suddenly costs triple, procurement needs to bring options to the table fast. The trick is knowing which specs are must-match and which can be safely equal-or-better so your recommendation actually gets approved.

This guide walks you through what to check before sending a substitute up for review, so you save time and avoid frustrating back-and-forth.

Read More: Understanding Form-Fit-Function For Electronic Components

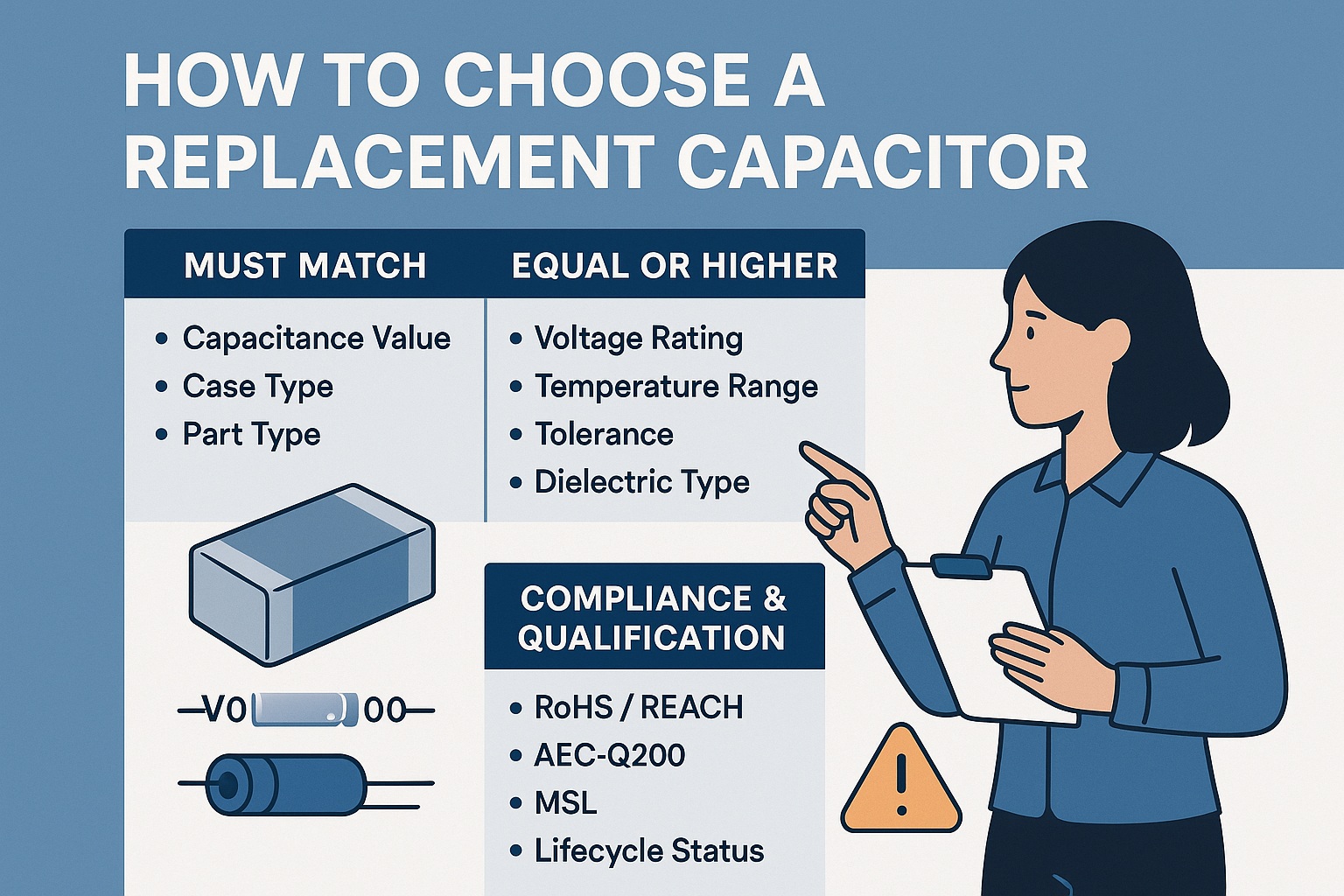

Specs That Must Match Exactly

If these don’t align with the original capacitor, the engineer will likely reject your suggestion immediately.

Capacitance Value

This is the primary rating of the capacitor—measured in µF, nF, or pF.

If it changes, the circuit might not work as intended. Unless the engineer specifically says otherwise, find the exact same value.

Case Type

Same size, same shape, same footprint. If the replacement won’t fit on the board or into the housing, it’s a non-starter.

Examples: radial leaded, axial, SMD 1206, SMD 0603.

Part Type

The construction category matters. Ceramic, electrolytic, tantalum, and film all behave differently.

For example:

Electrolytic parts are polarized—installing them backwards can destroy them.

Ceramic parts are non-polarized but can be sensitive to vibration.

Changing part type can alter performance, so keep it the same.

Specs That Can Be Equal or Higher

These are areas where going better is safe, but going lower needs engineering sign-off.

Voltage Rating

Match or exceed the original. A higher voltage rating is fine; a lower one risks failure under load.

Temperature Range

Maximum temperature: higher is okay.

Minimum temperature: same or lower (able to handle colder environments).

Tolerance

Tighter tolerance is usually fine. Looser tolerance can change circuit behavior—check with engineering first.

Dielectric Type

A higher-grade dielectric can improve performance if size and form factor match, but always confirm before changing.

Examples: X7R, X5R, C0G

Compliance & Qualification Checks

Even if the specs line up, these factors can still stop an alternate from being approved.

RoHS / REACH Compliance

Needed for any product sold in Europe, modern default components are no-lead.

Automotive Qualification (AEC-Q200)

Essential if the part is used in a vehicle system.

Moisture Sensitivity Level (MSL)

Higher MSL parts need special handling before soldering, or they can fail during assembly.

Lifecycle Status

Avoid parts that are discontinued, obsolete, or flagged “Not Recommended for New Designs (NRND).â€

Takeaway for Procurement

When you’re sourcing alternates:

-

Start with exact matches for capacitance, case type, and part type.

-

For other specs match or exceed—but never downgrade

-

Check compliance and qualification requirements before proposing.

Bringing the engineer a well-researched alternate shows you understand both sourcing realities and technical needs—making approvals faster and less painful.

Read More: Expert Guide to Cross-Referencing Electronic Components

**Want cross-references at no cost?** Visit X-Refs.com, for comprehensive alternates, parametric differences, and real-time inventory.