Ever found yourself scrambling because a critical part suddenly went obsolete? Or sat through one of those soul-crushing shortage meetings where no one has a backup plan? Welcome to the world of Component Lifecycle Management (CLM), your ticket to staying ahead in the fast-paced game of electronic component sourcing.

If you want to keep your supply chain humming, your inventory optimized, and your stress levels in check, mastering CLM isn’t optional. It’s essential. Let’s dive into what it is, why it matters, and how you can absolutely kill it at lifecycle management.

1. What is Component Lifecycle Management, Anyway?

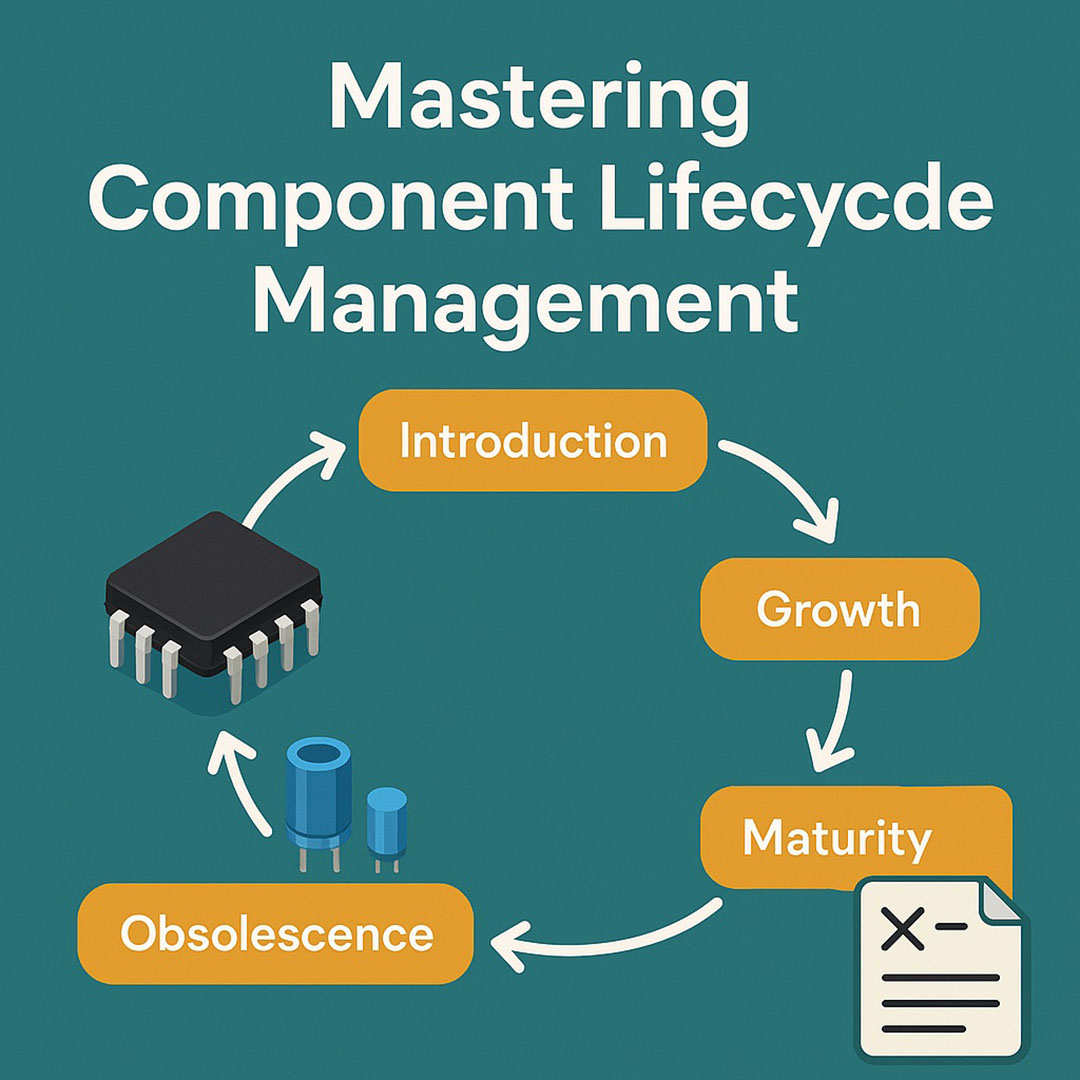

Think of electronic components like living products. They’re born, they grow, they peak, and then, whether you’re ready or not, they retire. Component Lifecycle Management (CLM) is the process of tracking, analyzing, and managing each stage of this journey.

Here’s the typical lifecycle:

-

Introduction: The shiny new part hits the market.

-

Growth: Demand surges as adoption picks up.

-

Maturity: Sales level off, and the part becomes standard.

-

Decline: Demand starts to fade as newer tech takes over.

-

Obsolescence: The manufacturer pulls the plug.

Why It Matters:

If you don’t actively track these stages, you risk waking up one day to find your go-to component is discontinued. That could leave your production line, and your job satisfaction, hanging.

Key Takeaway:

CLM isn’t just about tracking parts. It’s about anticipating problems before they blow up.

2. Why CLM is Your Supply Chain’s Secret Weapon

You already know the electronics supply chain is no walk in the park. Between global shortages, fast-moving technologies, and shifting market demands, surprises are guaranteed. But CLM gives you control in a world of uncertainty.

Here’s why it’s a game-changer:

-

Proactive Obsolescence Management: You can start sourcing alternatives or building buffer stocks long before the last-time-buy notice lands on your desk.

-

Inventory Optimization: Aligning purchase volumes with lifecycle stages keeps you from hoarding parts you won’t use or running out of parts you can’t replace.

-

Strategic Supplier Engagement: You’ll have solid data to negotiate long-term supply agreements or secure last-minute buys.

Real Talk:

Have you ever scrambled to buy a part after it went end-of-life (EOL) and found it only on the gray market at double the price? That is exactly the kind of nightmare CLM can help you dodge.

3. Electronic Components Move Fast, So Should You

Semiconductors, capacitors, resistors: they don’t stick around forever. Technology cycles are brutal. New versions come out. Manufacturers consolidate. Some parts barely make it to maturity before something shinier steals the spotlight.

How to Keep Up:

-

Monitor Manufacturer Communications:

-

Stay on top of Product Change Notifications (PCNs) and End-of-Life (EOL) announcements.

-

Subscribe to direct updates from key suppliers.

-

-

Use Cross-Referencing Tools:

- Always have a Plan B. Tools like SiliconExpert, IHS Markit, and Octopart can help you quickly find functional equivalents.

-

Plan for Lifecycle Stages:

- When you start sourcing, ask yourself: Will this part still be around when we need it in two years?

Example:

You might find a killer price on a microcontroller. However, if it’s already in the decline stage, that bargain could cost you a fortune later in redesigns and supply scrambling.

4. Inventory Optimization: Buy Smart, Not Just Cheap

You don’t want to overstock parts that are nearing obsolescence or understock those that are mission-critical. That’s where Inventory Optimization tied to lifecycle stages saves your budget and your sanity.

Practical Tips:

-

For New Components:

- Keep initial stock lean until the part’s stability in the market is proven.

-

For Maturing Components:

- This is your sweet spot. It’s safe to commit to bulk buys if forecasts support it.

-

For Declining Components:

- Time to scale back purchases, verify alternates, and potentially place last-time buys.

-

For Obsolete Components:

- Either you’ve got a lifetime buy strategy or you’re in a risky game sourcing from brokers.

Pro Tip:

Track inventory alongside lifecycle status in your ERP system. Set alerts for parts that enter the decline phase so you can act before it’s too late.

5. Obsolescence Management: Don’t Get Blindsided

Let’s face it, obsolescence is inevitable. However, getting blindsided by it isn’t.

Build Your Obsolescence Game Plan:

-

Lifecycle Forecasting: Use tools and supplier data to predict when parts are likely to become obsolete.

-

Risk Assessments: Map out which components are single-sourced or have no known alternatives.

-

Replacement Planning: Start validating cross-referenced parts long before the originals disappear.

Example:

A smart procurement team once avoided a million-dollar redesign by spotting an EOL notice early and securing a last-time buy to cover the remaining product life. That’s how you save the day.

6. The Power of Cross-Referencing: Always Have a Backup

One of the best tricks in the procurement playbook is cross-referencing.

When you know the electrical, mechanical, and performance requirements, you can often find equivalent parts that keep production moving, even if your preferred component vanishes.

Actionable Steps:

-

Build a Cross-Reference Database: Don’t wait until there’s a fire. Keep alternates logged and approved.

-

Qualify Substitutes Early: Work with engineering to test and approve alternates before you need them.

-

Use Trusted Tools: Platforms like X-refs, FindChips and SiliconExpert can help you validate substitutes quickly.

Why It Matters:

Having pre-approved alternates saves you from last-minute panic buys and keeps your lines running smoothly.

7. Wrapping It Up: Be the Procurement Hero

Here’s the bottom line: Component Lifecycle Management is your professional superpower. It keeps your supply chain resilient, your costs controlled, and your hard work visible.

If you:

-

Track lifecycles proactively,

-

Optimize your inventory with lifecycle in mind,

-

Manage obsolescence like a boss, and

-

Always have backup plans through cross-referencing,

You’ll not only protect your company’s operations, but you’ll also boost your own procurement credibility.

Nobody likes a last-minute scramble. With smart lifecycle management, you’ll be the one who’s always two steps ahead.